product details

EVOH Plastic characteristics:

1. The significant feature of EVOH is its good barrier and processability to gases

2. Transparency and glossiness

3. Mechanical strength and scalability

4. Excellent wear resistance, cold resistance, and surface strength.

◎ The host is composed of Φ 52/120/ Φ 65/ Φ 52 consists of 4 extruders, capable of producing and processing high barrier performance sheets with 4, 5, and 7 layers.

Adopting precision distribution technology, proportional measurement, fixed flow channel, more accurate layering, and more stable pressure. The thickness error of EVOH layer should be controlled within ± 0.015mm.

Adopting melt metering control to achieve closed-loop control in the extruder, resulting in more uniform extrusion.

The entire line adopts human-machine interface display, PLC control, variable frequency speed regulation, and is equipped with online powder technology to achieve automation and cleaning.

Three roll arrangement: vertical type structure, suitable for processing materials of various thicknesses.

◎ Large winding diameter (up to 1500mm) variable frequency drive, constant tension control.

Jinwei's new PP/PS/EVOH sheet production line continues the advantages of high production and low energy consumption in the past, while also keeping up with the times and achieving higher cost-effectiveness

Product features: Intelligent, user-friendly structural design, high yield and low energy consumption

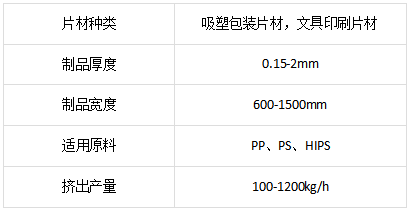

Equipment model: GWS L=600mm-1500mm Production capacity: 100kg/h-1200kg/h

Applicable enterprises: food packaging field, electronic product packaging field, stationery field, etc

Since its establishment, the company has been focusing on the research and development and production of plastic sheet extrusion production equipment. Through continuous innovation and practice, the PP/PS sheet extrusion equipment has been improved to achieve better performance and more humanized structure.

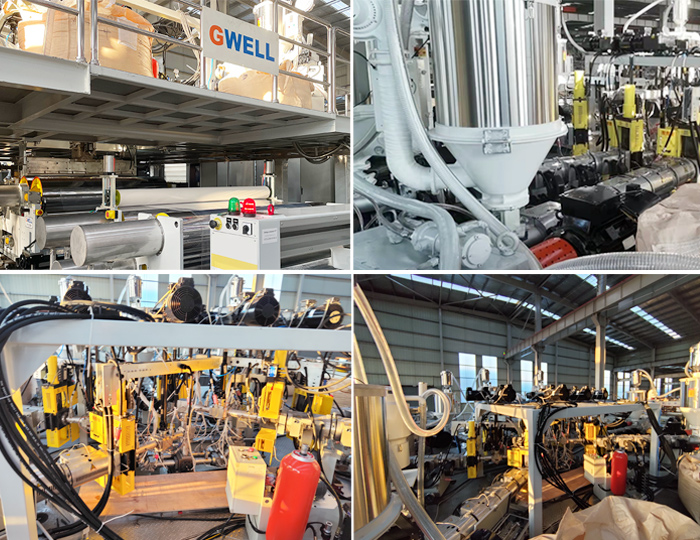

PP/PS blister packaging sheet, PP stationery sheet extrusion production line:

According to different product requirements, the PP/PS sheet extrusion production line can produce single-layer, double-layer, and multi-layer co extruded sheet products, widely used in the packaging and stationery fields.

PP/PS single-layer and multi-layer sheets can be directly used for packaging food and electronic products after being blistered.

PP transparent sheets, frosted sheets, dual color sheets, etc. can be used for stationery sheets.

With the "one click acceleration" function, this function allows the equipment to achieve low-speed adjustment and high-speed production, greatly reducing the waste of raw materials caused by the adjustment process. The intelligent advanced control system has a fast network transmission speed, greatly reducing information transmission errors, and making the speed, pressure, and material transportation of the equipment more stable

The winding part adopts servo control, which is more accurate and has speed synchronization function with the entire machine, making winding more convenient, simple, and safer

Through centralized control, it is possible to browse all device information on one screen, such as current, pressure, speed, temperature, vacuum pressure, etc., making operation simpler;

The entire set adopts Siemens variable frequency servo control and Ethernet transmission technology control, achieving high efficiency, precision, stability, and safety. Quickly locate errors when equipment malfunctions and enable remote maintenance. Channel level diagnosis and error analysis can be achieved through HMI, greatly reducing debugging and production downtime. A highly digitized system makes debugging simpler and maintenance more convenient;

A complete after-sales service system, from equipment installation and debugging to the production and manufacturing of high-quality products, and providing lifelong technical support, allowing customers to worry free.

- Previous article:first a piece of writing

- Next article:Last article

Boutique Recommendation