product details

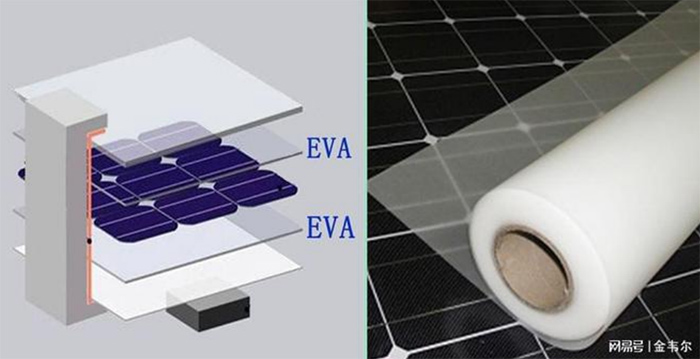

1、 Introduction to EVA solar adhesive film

EVA adhesive film is a thermosetting adhesive film that can be used for laminating glass. Due to its advantages in adhesion, durability, optical properties, etc., EVA adhesive film is increasingly widely used in current components and various optical products.

1. Due to the excellent properties of EVA film, it is a commonly used packaging material for photovoltaic panels. It has the following advantages:

(1) Good transparency and strong adhesion can firmly bond the glass and silicon wafers on photovoltaic panels.

(2) Having good durability can resist high temperatures, humidity, and ultraviolet radiation, significantly improving the service life of photovoltaic panels.

(3) EVA film has no adhesion at room temperature, making it easy to cut. After hot pressing, thermal crosslinking curing and adhesive reinforcement reactions occur, resulting in permanent adhesive sealing.

After several years of development, the adhesive film has been domestically produced and exported to foreign countries. In terms of raw materials, only three domestic companies were able to produce photovoltaic grade EVA raw materials. As people's awareness of environmental protection has been strengthened in recent years, especially in China, the goals of "carbon neutrality" and "carbon peaking" have been put forward. Forcing people's desire for new energy. Several large domestic chemical enterprises have established EVA raw material production lines, and it is expected that by 2024, there will be about 8 domestic enterprises capable of producing photovoltaic grade EVA. Gradually breaking away from the monopoly of foreign enterprises in terms of raw materials.

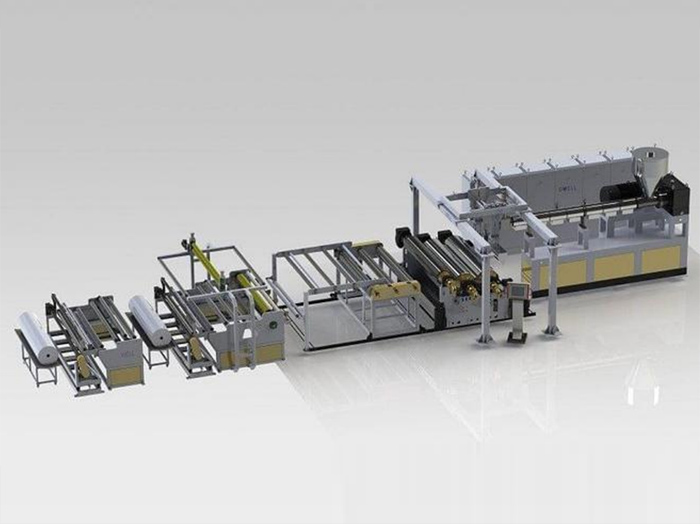

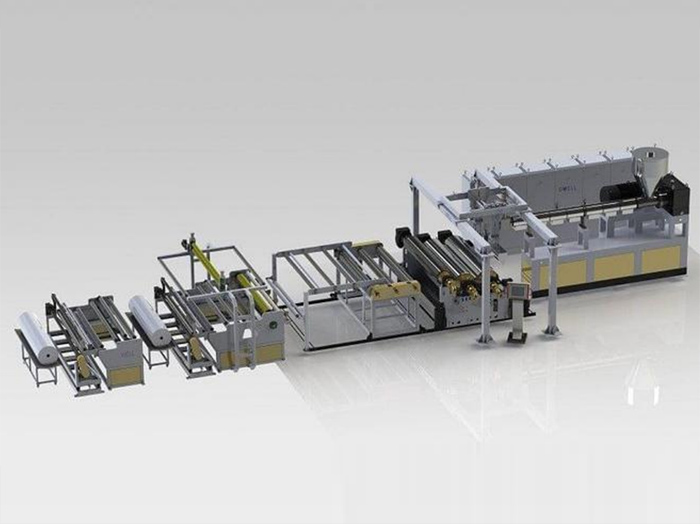

2、 Introduction to EVA film production equipment

The EVA film production line adopts a casting process to produce EVA solar cell packaging film. The main raw material is vinyl acetate copolymer, also known as EVA, which is extruded by heating and casting after adding additives.

(1) The extruder adopts EVA specialized single screw extrusion, and the screw barrel constant temperature circulating water cooling system solves the technical difficulties of EVA plasticization and non crosslinking.

(2) The roller body adopts double-sided embossing and solves the technical difficulties of adhesive film sticking to the roller.

(3) The cooling part adopts cooling rollers and stress relieving cooling beds to ensure smooth operation and full shaping of the adhesive film, ensuring a shrinkage rate of less than 3%

(4) The entire line adopts PLC fully automatic control to achieve human-machine interface operation.

(5) The production line is equipped with an online quality monitoring and control system to ensure product qualification rate.

(6) Patented design micro tension winding machine, with a production line speed of up to 18m/min

- Previous article:first a piece of writing

- Next article:Last article

Boutique Recommendation