product details

1、 Introduction to Flame retardant PC raw materials: Flame retardant PC raw materials are colorless, transparent, heat-resistant, impact resistant, flame retardant, and have good mechanical properties within normal usage temperatures. Compared with ordinary PC raw materials, it has good insulation and flame retardancy.

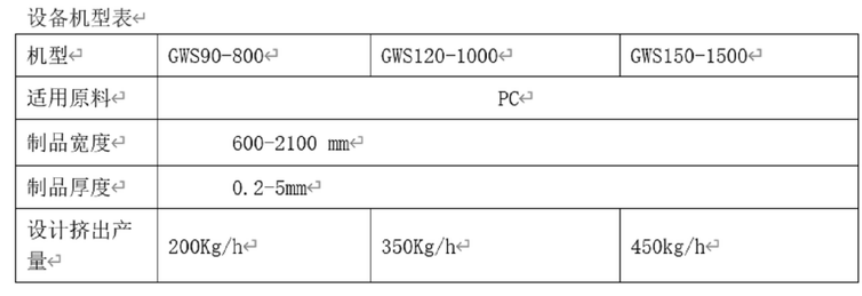

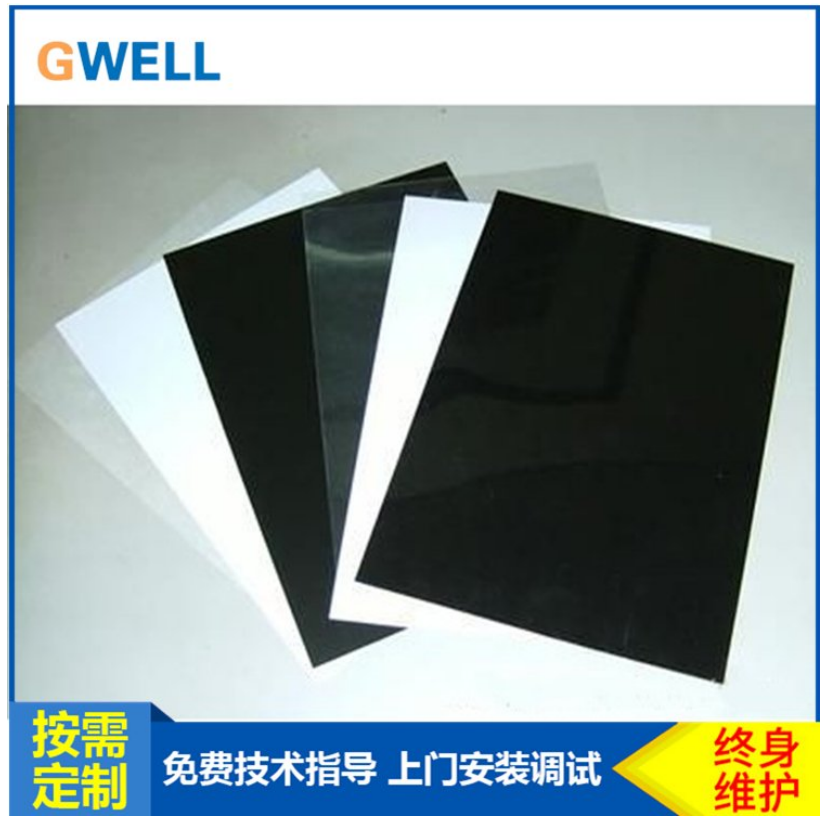

2、 Introduction to Flame retardant PC sheets, also known as PC insulation sheets. Mainly used for various types of electronics, appliances, batteries, etc. With the development and popularization of new energy vehicles, the demand for battery surgery is becoming increasingly high, and the demand is also increasing. Due to its excellent performance, flame-retardant PC sheets have gradually replaced the original PP battery casing and top cover. The development prospects are enormous. Our Kinwell company's PC sheet production machine can produce PC sheets with a thickness of 0.2-6mm and a width of 600-2100mm. Having good physical properties.

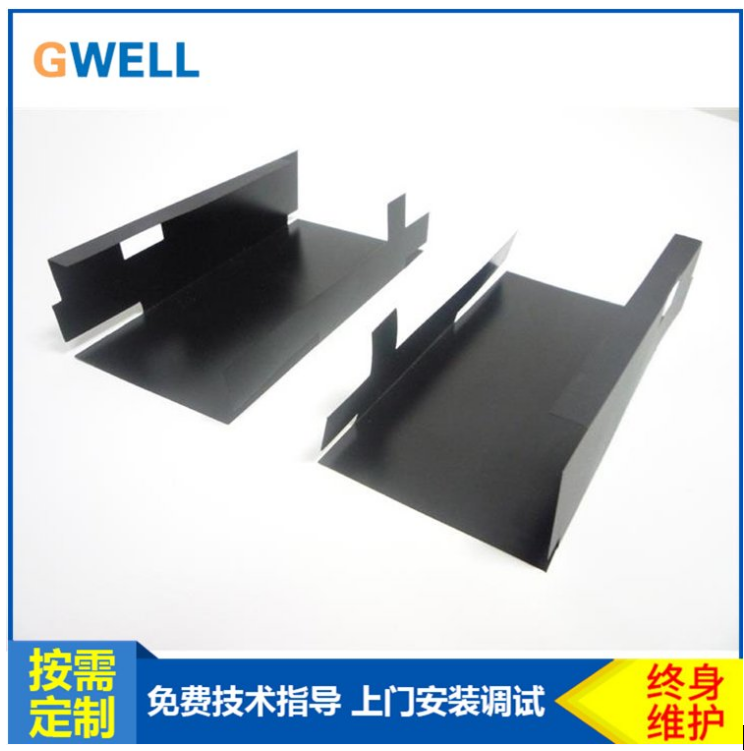

3、 Introduction to PC Insulation Sheet Production Machine: Our machine uses PC specialized screws to ensure complete plasticization of PC raw materials, and to prevent poor or over plasticization caused by screw reasons, which can lead to defects such as crystal dots, black spots, and white spots on the sheet. The roller adopts a special heat dissipation design to prevent uneven thickness of the sheet material due to uneven heating and cooling of the roller surface. The transmission components adopt servo control, making the transmission more precise. Ensure that the sheet material will not be pulled out and there will be no wrinkles on the surface. High automation of the entire equipment reduces labor intensity and increases work efficiency.

- Previous article:first a piece of writing

- Next article:Last article

Boutique Recommendation