product details

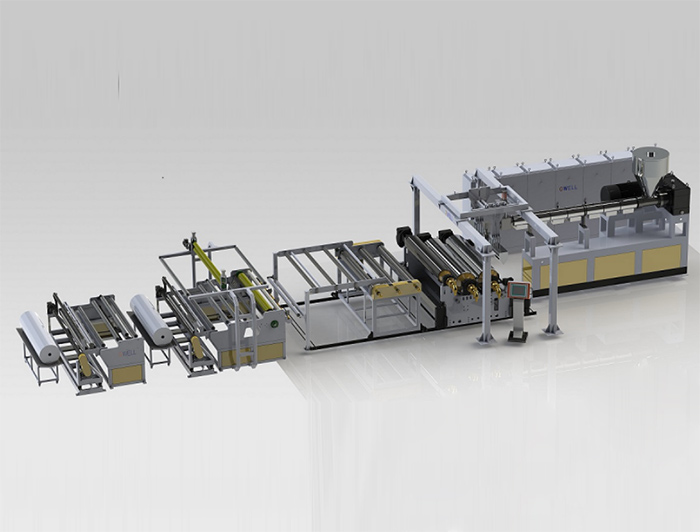

EVA solar adhesive film low-temperature extrusion production line

EVA solar cell adhesive film is used for solar cell packaging. After lamination and curing, it is bonded and sealed, playing a high transmittance, preventing water vapor penetration, high and low temperature resistance, and UV resistance role in battery components, ensuring the stable and efficient use of battery components. It is a durable and reliable packaging material.

Performance characteristics of Jinwei EVA film production line: (1) The salivation extruder adopts EVA single screw extrusion, and the screw barrel constant temperature circulating water cooling system solves the technical difficulties of EVA plasticization and non crosslinking. (2) The roller body adopts double-sided embossing and solves the technical difficulties of adhesive film sticking to the roller. (3) The cooling part adopts cooling rollers and stress relieving cooling beds to ensure smooth operation and full shaping of the adhesive film, ensuring a shrinkage rate of less than 3%. (4) The entire line adopts PLC fully automatic control to achieve human-machine interface operation. (5) The production line is equipped with an online quality monitoring and control system to ensure product qualification rate. (6) Design a micro tension winding machine, with a production line speed of up to 14m/min for the entire machine

EVA glass laminated film, widely used in:

Deep processing of special glass such as safety flat laminated glass, arc laminated glass, process laminated glass, bulletproof glass, color changing laminated glass, conductive intelligent glass, solar cell, etc.

EVA hot melt adhesive casting film, embossed film, widely used in:

Sanitary products: medical surgical gowns, baby diaper film, women's sanitary napkin bottom film capsule, adult diaper film, pet pad film, disposable bed sheets, etc.

Daily necessities: umbrellas, raincoats, suits and jackets, various tablecloths, shower hats, shower curtains, aprons, chair covers, etc.

Packaging supplies: computer electrical dust cover, cosmetic soft packaging, shopping bags, gift bags, archive bags, etc.

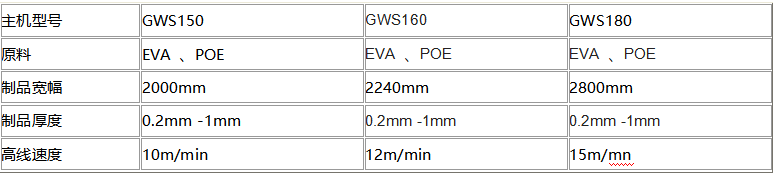

EVA film production line parameters (please consult sales engineers for details)

- Previous article:first a piece of writing

- Next article:Last article

Boutique Recommendation