product details

1. The thickness of ETFE fluorine film is generally between 20 and 40 μ m. The width can reach 1300mm, and the production line speed is 8-30m/min. Other specifications can be negotiated and customized; 2. ETFE film is a high-quality alternative material in transparent building structures. Its unique self-cleaning surface makes it anti fouling and easy to clean. Usually, rainwater can remove the main dirt; 3. ETFE film has the characteristics of anti-aging, corrosion resistance and long service life. The general service life is 25-35 years; 4. The ETFE film is lightweight, has a high fire resistance rating, and does not drip during combustion; 5. The ETFE film has a high transmittance, which can reach over 90%; 6. Environmentally friendly and recyclable: ETFE membranes can be recycled and reused to produce other ETFE products.

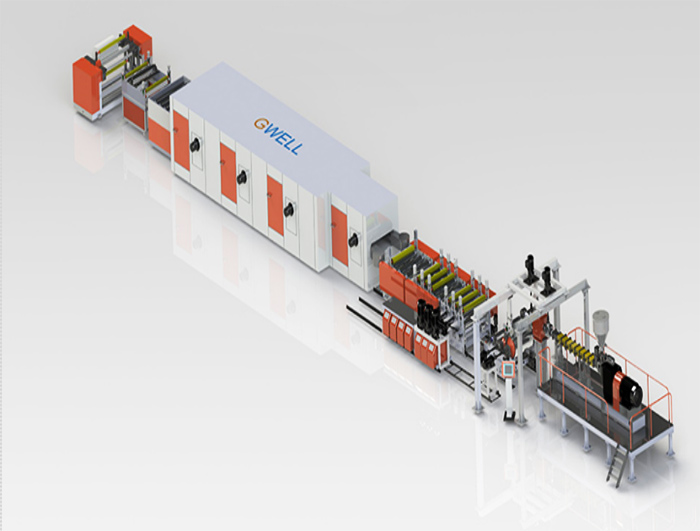

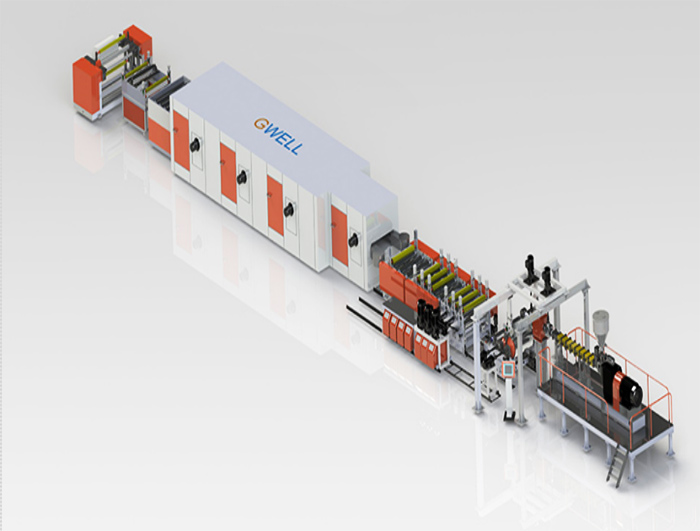

ETFE film casting production line

ETFE film is one of the fluorinated plastics, which has good transparency, self-cleaning, insulation, moisture heat resistance, and aging resistance, and is widely used in various fields. ETFE fluoroplastic film is prone to thermal decomposition and corrosion of processing equipment and molds during hot working due to the presence of fluorine. Therefore, processing equipment and process are different from ordinary thermoplastics. This production line adopts specially designed equipment and process technology, and has successfully developed a casting extrusion production line for ETFE and other fluoroplastic films.

The production line uses specially designed extruders and casting heads to produce ETFE films through extrusion casting.

Features of the production line:

1. An extruder made of special high-temperature and corrosion-resistant steel to achieve stable extrusion of fluoroplastics;

2. Cooperate with domestic universities and research institutions in technical cooperation, and design screw structures and die structures specifically for the unique characteristics of fluorine materials, in collaboration with

Special processing techniques such as molding and winding are used to achieve rational, industrialized, and large-scale production of fluoroplastic products;

3. The overall configuration is practical and reasonable in design, with PLC touch screen control and overall interlocking control, making it convenient and safe.

Product features:

1. The thickness of ETFE fluorine film is generally between 20 and 40 μ m. The width can reach 1300mm, and the production line speed is 8-30m/min. Other specifications can be negotiated and customized;

2. ETFE film is a high-quality alternative material in transparent building structures. Its unique self-cleaning surface makes it anti fouling and easy to clean. Usually, rainwater can remove the main dirt;

3. ETFE film has the characteristics of anti-aging, corrosion resistance and long service life. The general service life is 25-35 years;

4. The ETFE film is lightweight, has a high fire resistance rating, and does not drip during combustion;

5. The ETFE film has a high transmittance, which can reach over 90%;

6. Environmentally friendly and recyclable: ETFE membranes can be recycled and reused to produce other ETFE products.

Main uses of the product:

1. The thickness of ETFE membrane material is usually less than 0.20mm, making it a transparent membrane material. ETFE membrane materials are used in membrane structures and are often made into air cushions. The early ETFE project has a history of more than 20 years, with Eden in the UK as the main stadium for the 2008 Beijing Olympics - the swimming pool - using this membrane as the roofing material. "Water Cube" is a large membrane structural engineering of Zui, and the building periphery is made of advanced environmental friendly and energy-saving ETFE (tetrafluoroethylene) membrane materials. ETFE film can not only be used as a film for construction and agriculture, but also for automotive windshield films, anti fouling inner and outer packaging materials, battery separators, adhesive containers, conveyor belts in the food industry, solar receivers, flexible printed circuit boards, computer wires, medical packaging films, etc;

2. ETFE, as a curtain wall or roof material, is a new application field developed in recent years and has been applied in over 100 projects. The main stadium of the 2008 Beijing Olympics, the swimming pool, used ETFE film as the roof material, consisting of 3000 air bags, covering an area of 110000 square meters. The total amount of ETFE raw materials used reached 200 tons. However, currently there are no enterprises in China that process high quality wide width ETFE films. After the 2008 Olympics, the usage of ETFE will increase exponentially, leading the fluoroplastic processing industry to advance towards the mid market.

Specific specifications can be customized according to customer requirements.

ETFE film production line

ETFE membrane materials have a wide range of applications in aerospace, photovoltaic industry, electronic semiconductor field, 5G and thin film construction, etc. However, the production technology of ETFE is currently difficult, and most of its core production and processing key technologies are mastered by foreign companies. However, Kinwell's ETFE film production line can truly be used to produce high-end film products with a wide range.

After years of deep cultivation in the fluorine material industry, Jinwei Company has now taken ETFE film products as a breakthrough point and achieved the commercialization of high-quality film products. Previously, there was no lack of research on ETFE thin film products among Chinese people. However, due to various reasons such as insufficient company size and technical barriers, the final products still cannot compare with foreign products. Jinwei Machinery combines years of experience and innovative drive to conduct comprehensive and meticulous polishing on raw materials, processes, and equipment, producing high-end ETFE film equipment that is comparable to tens of millions of foreign equipment and can produce a 1.6m wide width. Innovation is the driving force of an industry, and the high prices of raw materials for ETFE undoubtedly pose enormous risks and challenges for an equipment company. However, in this competition with foreign companies, we have gradually stood up and are able to produce our own raw materials and equipment. Even though various aspects are still immature now, there is great potential for the future.

Jinwei Machinery's ETFE casting film production line drew on the experience of similar production lines in Japan and conducted in-depth research and improvement on all parts of screws, molds, forming, cooling, and winding. A set of modular processing systems for ETFE materials has been developed.

Summary of production line characteristics

The core part of the entire production line is made of high-temperature and corrosion-resistant Hastelloy steel, which is durable

2. The entire line adopts a fully automated intelligent operating system, which is controlled by PLC and integrated into the central control screen. The melting temperature and pressure can be adjusted at any time

3. Special design of the screw ensures good plasticization of the finished product, without defects or crystal points

4. The mold undergoes repeated rheological analysis experiments to ensure compatibility with boring materials

5. The forming system is independently servo controlled, and the temperature is controlled by an independent mold temperature machine. The temperature difference on the roller surface does not exceed one degree.

6. Equipped with a fully automatic micro tension winding machine, efficient and energy-saving, saving manpower.

- Previous article:first a piece of writing

- Next article:Last article

Boutique Recommendation