product details

Introduction to Velcro Production Equipment

The production equipment for Velcro mainly includes weaving machines, hot melt machines, slitting machines, welding and cutting machines, welding machines, and other equipment. So, how do Velcro production equipment produce Velcro? Below, the editor will explain.

1. The welding machine of the Velcro production equipment can meet the customer's choice of Velcro pattern. It adopts the principle of ultrasound, and during welding, it can present different patterns and welding points at the Velcro welding site.

2. The welding and cutting machine for Velcro production equipment is a specially developed equipment that integrates welding and cutting. It is mainly used to cut Velcro into designed shapes and can be directly connected together using welding technology.

3. The slitting machine of the Velcro production equipment can achieve automated and intelligent control. The entire process of automatic feeding and slitting does not require manual labor, and the slitting cuts are neat and can also be automatically sealed.

Advantages of extruded Velcro products

Stable quality and excellent precision.

Ultra light, ultra-thin, and super strong lateral tensile force, with an average of over 1000g/cm.

The bite gap between the hook hairs is only 1mm, (the traditional hook hair surface is around 2-3mm).

The new type of ejection hook is less prone to yarn hooking, with a delicate hook shape and a good appearance and texture when sewing on ready-made clothes.

No sewing, high frequency pressing, can create different shapes.

Can be paired with reverse printing to enhance brand image and achieve overall product bonus effect.

Suitable for application in industries such as automobiles, ready-made clothing, backpacks, footwear, and medical equipment.

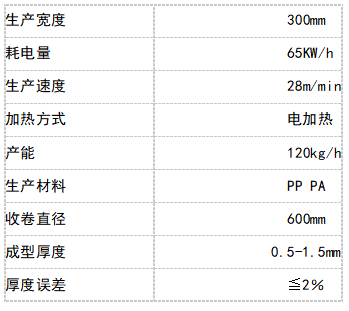

PA Ejection Hook Velcro Equipment Product Introduction

1. Service conditions

Power supply 380V/3P/50Hz

Water temperature and dosage 10 ℃ -12 ℃, 15m3/h or

20 ℃-25℃,30m3/h

Air pressure 0.6-0.8Mpa

2. Use material PP or PA

3. Product specification L=300mm, δ= 0.15-0.3mm

4. Extrusion output 75kg/h

Velcro product introduction

HOOK&LOOP, also known as a buckle or buckle (which makes a clicking sound and acts as a button), is a commonly used connecting accessory on clothing, divided into two sides: male and female. One side of the Velcro is made of small, soft fibers with round hair (LOOP), and the other side is made of harder, hooked bristles (HOOK). Ordinary clothes (thorns) HOOK on top.

Ejection hook is a type of Velcro, made of ultra-thin material with a soft hook surface. It can be used in conjunction with various soft surface materials, especially adhesive cloth. It is a high-end product in the Velcro series, available in both transparent and opaque materials. According to the hook type, it can be divided into four varieties: No. 2 thin single hook, No. 3 thin double hook, No. 4 thick hook, and No. 5 reverse half bend hook. The difference lies in the height and frequency of use of the hook type, as well as the density of the hook type, ranging from 100 to 200 pieces per square centimeter.

characteristic:

Ejection hook is a clothing production auxiliary material, which is similar to adhesive buckle. The most common type of device for measuring blood pressure is the one where the doctor wraps a piece of cloth around our arm every time we take measurements? The adhesive function on that piece of cloth is the adhesive buckle, which is hooked on one side and has a fur on the other. When torn open, it will make a loud noise, which is the adhesive buckle. The purpose of the injection hook is similar to this hook surface, usually used in combination with magic cloth to replace this adhesive buckle.

Ejection hooks are considered a new type of special excipient in the current excipient industry, and it is an inevitable trend for them to replace Velcro straps in the future.

Ejection hook is a special high-end Velcro, which is a commonly used connecting accessory. It only has a hook surface (HOOK), and the fur surface can be paired separately.

The hook types of the Ejection Hook Velcro include 1-2 # thin hook, 3 # double hook, 4-5 # thick hook, and the mushroom head is generally made of polypropylene material.

The hook shapes of 2 # and 4 # hooks are the same, both in the rrrr font, while 3 # hooks are double hooks in the YYY font. Different hook shapes can be used on different products, and 2 # injection hook Velcro is suitable for use on baby cloaks, baby clothes, etc; 3 # Ejection Hook Velcro is suitable for use on high-end clothing and other products; 4 # Ejection Hook Velcro is suitable for use on high-end tents, backpacks, etc;

It can also be mixed and used, but the effect is not as good. At the same time, there are three types of fur surfaces that can be used in conjunction with the injection hook Velcro, namely, a fleece fabric, a non scratching Velcro, and a regular Velcro fur surface. The 2 # injection hook Velcro and 3 # injection hook Velcro have better adhesion when paired with the fleece fabric, but have average adhesion when paired with other materials. The 4 # injection hook Velcro has the strongest adhesion when paired with a regular Velcro fur surface; Other stickiness is average.

Velcro, which is commonly used in our daily lives, is mainly used on clothes, shoes, and hats. With the advancement of technology, the hook surface of Velcro has gradually been replaced and replaced by the ejected hook.

- Previous article:first a piece of writing

- Next article:Last article

Boutique Recommendation