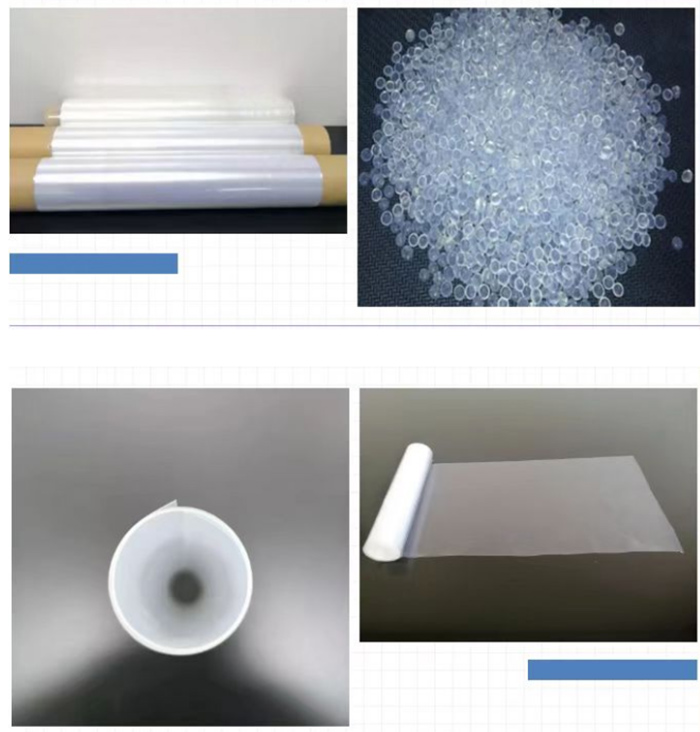

product details

The Chinese name of ETFE casting film equipment ETFE is ethylene tetraethylene copolymer. The thickness of ETFE film is usually less than 0.20mm, making it a transparent film material. Jinwei Company produces ETFE film equipment; The equipment mainly consists of an extruder, screen changer, metering pump, mold, forming roller winding machine, etc. Due to the corrosiveness of ETFE material during the plasticization process to metal materials, all materials in contact with the material are made of special materials to ensure the safe and stable production of the product.

The service life of ETFE film is at least 25-35 years, making it an ideal material for multi-layer movable roof structures. This membrane material is often used for two-layer or three-layer inflatable support structures with a span of 4 meters, and can also be increased according to the geometric and climatic conditions of special engineering projects. The length of the membrane is based on ease of installation, generally ranging from 15 to 30 meters. Small span single-layer structures can also be used in smaller sizes.

ETFE casting film production line

Features of the production line: 1. Extruder made of special high-temperature and corrosion-resistant steel, achieving stable extrusion of plastics; 2. Cooperate with universities in technology to design screw structures and die head structures tailored to the unique characteristics of materials, and cooperate with special processing techniques such as forming and winding to achieve rational, industrialized, and large-scale production of plastic products; 3. The overall configuration is practical and reasonable in design, with PLC touch screen control and overall interlocking control, making it convenient and safe. Product features: 1. The thickness of PVDF film is generally between 20 and 40 μ m. The width can reach 2500mm, and the production line speed is 5-100m/min. Other specifications can be negotiated and customized; 2. ETFE film is a high-quality alternative material in transparent building structures. Its unique self-cleaning surface makes it highly resistant to dirt and easy to clean. Usually, rainwater can be the main source of dirt; 3. ETFE film has the characteristics of anti-aging, corrosion resistance and long service life. The general service life is 25-35 years; 4. The ETFE film is lightweight, has a high fire resistance rating, and does not drip during combustion; 5. The ETFE film has a high transmittance, which can reach over 90%; 6. Recyclability: ETFE membrane can be completely recycled and reused to produce other ETFE products

etfe film

ETFE thin film has a long-term stable operating temperature from -200 ° C to 165 ° C, making it an ideal release material for building, solar energy, semiconductor packaging, and composite materials.

PFA film

PFA film can withstand chemical corrosion, stress tear resistance, and excellent electrical performance for long-term operation at 260 ° C. It can be applied in high-frequency copper clad plates and insulation of wires and cables.

FEP thin film

FEP thin films can be thermally welded, formed, and composite with various materials. They are commonly used as excellent hot melt adhesive materials and are widely used in fields such as electronics and electrical, mechanical equipment, instruments and meters, medical devices, chemical engineering, energy, aerospace, and so on.

The fluorine material film production line developed by Kinwell refers to the manufacturing processes of Germany and Japan, and the quality of the produced film can be comparable to imported films. The production line has the advantages of stable performance, high efficiency, energy conservation, and high degree of automation. All production lines are made of corrosion-resistant alloy materials to ensure long-term stable operation of equipment. Special screw design is designed for fluorine materials to ensure good product quality.

- Previous article:first a piece of writing

- Next article:Last article

Boutique Recommendation