product details

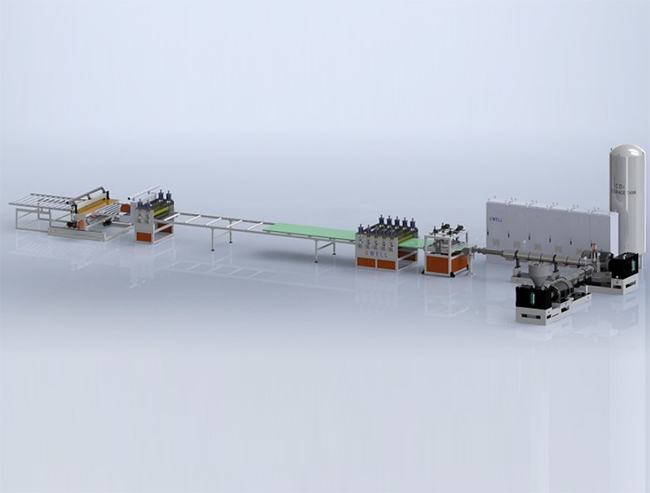

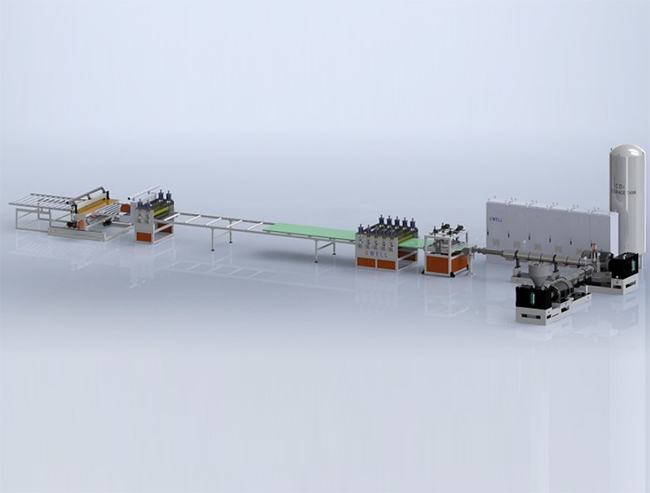

The XPS extruded polystyrene foam board (XPS) production line is generally divided into two types: carbon dioxide foam and Freon foam. The carbon dioxide foam XPS extrusion board complete production line from Jinwell Company is 100% carbon dioxide foam. The complete use of "CO2 combined foaming agent" has replaced the "fluorine series" foaming agent, greatly reducing the production cost of XPS extruded boards. Moreover, CO2 as a foaming agent is more environmentally friendly and conducive to sustainable development. The production line of this technology runs quickly and smoothly. The XPS extruded board produced has a width of 600mm-1200mm and a thickness range of 20-60mm. The average density is 30-45kg/m3, and its homogeneous closed cell foam structure makes the produced board stable, high compressive strength, and low water absorption. Jinwei XPS equipment comes in two types: single screw series extruder and co directional flat double screw series extruder, with specifications including φ 135/ φ 150 single screw extruder series and φ 75/ φ 150 co directional parallel twin series single screw extruder, done φ 95/ φ The 250 co directional parallel twin series single screw extruder is capable of processing ingredients composed of multiple components due to its excellent mixing efficiency. The plate forming is formed by vacuum negative pressure. The newly developed vacuum forming unit of Kinwell can reduce the product proportion and reduce the product production cost on the premise of ensuring the plate quality. Our company can achieve mutual switching between carbon dioxide foaming and Freon foaming, with mature technology. It is also possible to retrofit the Freon equipment with a carbon dioxide foaming device.

At present, most insulation boards in the market use Freon as a foaming agent, and Freon can cause significant damage to the ozone layer. Jinwei Company's environmentally friendly XPS extruded foam insulation board production line has many advantages, such as high automation, fast production speed, and sensitive operation, but its price is lower than similar foreign production lines. The extruded foam insulation board produced with this equipment is a green and environmentally friendly building material. It not only has long-lasting extremely low thermal conductivity, good dimensional stability, and weather resistance, but also has uniform foaming, delicate foam pores, high compressive strength, moisture resistance, non water absorption, easy construction and transportation, and is highly popular among users.

XPS extruded polystyrene foam board (XPS) has a perfect closed cell honeycomb structure and is currently recognized as an excellent insulation material in the market. It uses recycled EPS polystyrene board granulation as the main raw material to complete the product production process of extrusion foaming, shaping, traction and cutting. Its density, water absorption, thermal conductivity and steam permeability coefficient are lower than other types of plate thermal insulation materials, so it has the characteristics of good strength, light weight, impermeable, corrosion resistance, aging resistance, low price, etc., and is widely used in roof thermal insulation systems; Thermal insulation inside and outside the walls of cold storage, barracks, grain depots, and civil buildings; Ground construction aspects such as airport runways and squares; Civil engineering for highways and railways; In the partition system of buildings such as apartments, office buildings, factories, etc.

Performance characteristics:

1. Thermal insulation

It has the characteristics of high thermal resistance, low linearity, and low expansion ratio. Its structure has a closure rate of over 99%, forming a vacuum layer to avoid air flow and heat dissipation, ensuring its insulation performance is long-lasting and stable. Compared to the 80% closure rate of foam polyurethane, its leading advantage is self-evident. Practice has proved that the thermal insulation effect of 20mm thick XPS extruded insulation board is equivalent to 50mm thick foamed polystyrene and 120mm thick cement perlite. Therefore, this material is currently an excellent choice for building insulation.

2. High strength compressive strength

Due to the special structure of XPS board, it has extremely high compressive strength and strong impact resistance. According to different models and thicknesses of XPS, its compressive strength can reach over 150-500Kpa and can withstand ground loads of various systems. It is widely used in fields such as geothermal engineering, highways, airport runways, square ground, large cold storage, and interior decoration insulation.

3. Hydrophobic and moisture-resistant

Water absorption is an important parameter for measuring insulation materials. After absorbing water, the insulation performance of the insulation material decreases. At low temperatures, the water sucked in is prone to freezing, damaging the structure of the insulation material, and thus reducing the compressive and insulation performance of the board. Because the polystyrene molecular structure itself does not absorb water, the plate molecular structure is stable, and there is no gap, which solves the problems of water leakage, penetration, frosting, condensation and other problems of other materials.

4. Lightweight and easy to use

The fully closed cell foam chemical structure and honeycomb like physical structure of XPS board make it lightweight and high-strength, easy to cut, transport, and not easily damaged, and easy to install.

5. Good stability and corrosion resistance

During long-term use, it does not age, decompose, or produce harmful substances. Its chemical properties are extremely stable, and it will not degrade due to water absorption and corrosion, resulting in a decrease in its performance. It can still maintain its superior performance in high-temperature environments. According to relevant information, XPS extruded insulation boards can maintain excellent performance even after 30-40 years of use, and will not decompose or mold, without the volatilization of toxic substances.

XPS extruded insulation board production line parameters (please consult sales engineers for details)

- Previous article:first a piece of writing

- Next article:Last article

Boutique Recommendation