product details

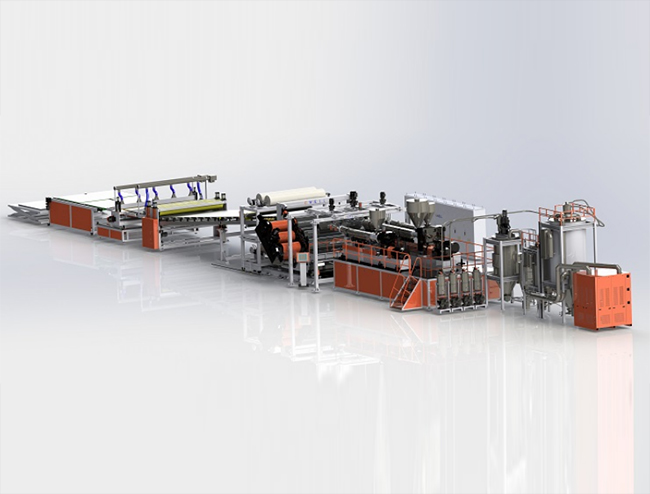

The PMMA acrylic sheet production line can continuously produce PP, PE, ABS, PMMA, PC, PS, PVC single-layer and multi-layer sheet products. The width of the sheet is 2000mm and below, and the thickness is 0.15-3mm.

Extruder: According to different materials, a single screw extruder (with or without exhaust) is selected. The screw adopts special mixing function and precise temperature control system to ensure high plasticization, high yield and stable extrusion of plastic.

Temperature control of ± 1 ℃ can accurately control the plasticizing process and the thickness of the sheet.

Screen change and mold: The hydraulic rapid screen change device ensures that the screen change does not leak, and the screen change is fast and effective; According to different materials, different structural forms are selected for the mold. The coat hanger type mold head adopts a page double throttling design, which is easy to adjust the flow distribution evenly, and the extrusion sheet thickness adjustment is more accurate.

Three roller calender: According to the thickness of the sheet, a 45 ° inclined three roller, vertical three roller, or horizontal three roller calender is used. The temperature control of the three rollers is independent of each other, and the gap between the rollers can be adjusted freely. The special design of the adjustable angle of the middle roller ensures the uniformity of the calender and the thickness of the sheet.

The thickness control of the sheet material adopts screw adjustment and pressure wheel bidirectional adjustment to accurately control the thickness of the sheet material. The independently controlled roller temperature control system can accurately control the temperature of the pressure roller drum to ensure uniform thickness of the sheet metal.

The plastic transparent sheet production line of Jinwei Company fully absorbs and digests the world extrusion technology from Europe and the United States. The main components are selected from high-quality products (such as screws, machine barrels, rollers, etc.), and the energy consumption, intelligence, automation indicators, safety standards, and process standards of the complete equipment are also included. The transparent board products produced are widely used in industries such as optics, home appliances, construction engineering, decoration, furniture, advertising, handicrafts, and other civil industries. And we have a matching team of process engineers to help users debug and produce high-quality products.

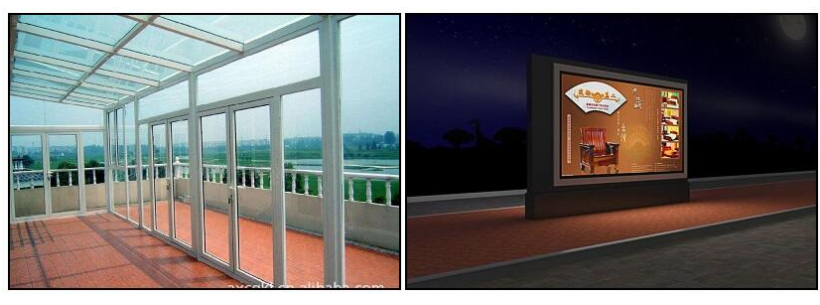

PC endurance board: strange decorations in gardens, amusement venues, and corridors and pavilions in rest areas; The interior and exterior decorations of commercial buildings, and the curtain walls of modern urban buildings; Transparent aviation containers, motorcycle windshields, aircraft, trains, ships, cars, steamships, submarines, and glass military police shields; The layout of telephone booths, advertising signs, and lightbox advertising display exhibitions; Expressway and urban overpass are separated by barriers.

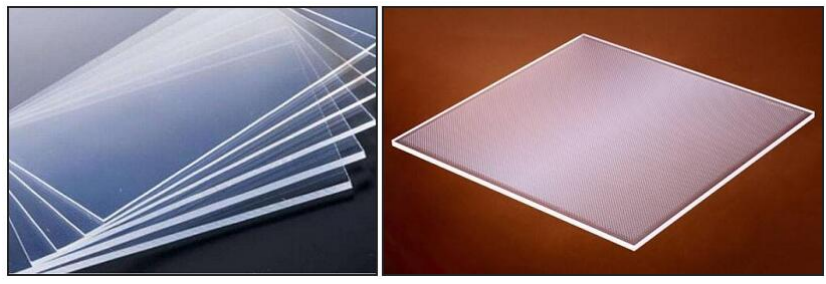

PMMA light guide plate: Guide the light flux of LED point light sources to be evenly distributed throughout the entire plane, utilizing reflection mechanisms to use light flux more efficiently and control light distribution.

PC and GPPS diffusion plates: Disperse the light flux, distribute the light evenly (some composite diffusion plates not only homogenize the light, but also control the angle of emission), and support the backlight structure to protect the optical materials below from damage.

PMMA (Acrylic), GPPS, MS board: widely used in instruments, instrument parts, lighting fixtures, decoration, building materials, aircraft, automotive parts, medical equipment, process products, electrical insulation materials, specimens, signs, and various light industry, cultural and educational, daily necessities, etc.

PET (modified) transparent thick plate: PET thick plate is processed with ordinary APET raw materials and special modified PET raw materials. Due to its superior cost-effectiveness, it can replace PC/PMMA/GPPS boards in many occasions, used in construction, decoration, advertising, and other fields. Our company's equipment can achieve a thickness of 8mm for APET and PETG.

- Previous article:first a piece of writing

- Next article:Last article

Boutique Recommendation