product details

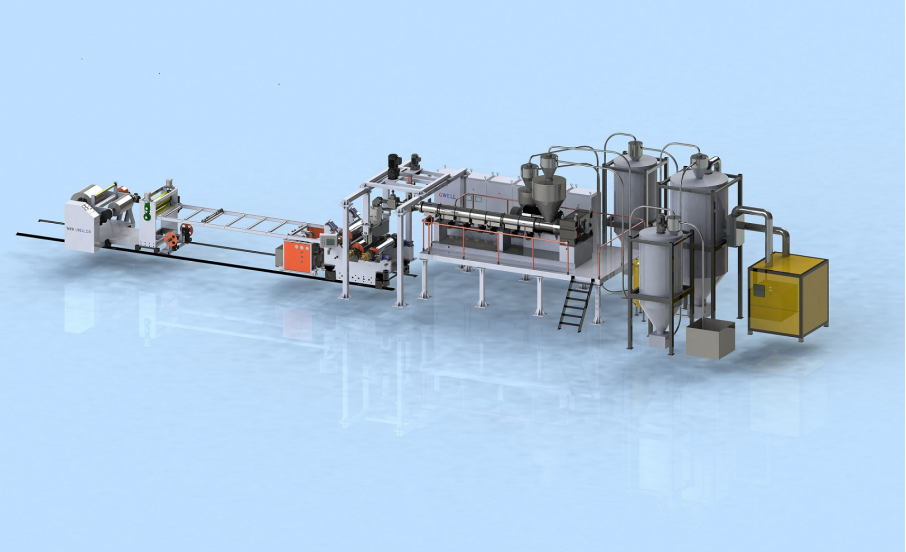

(This figure is a schematic diagram of the PET sheet single screw extrusion production line)

The Jinwei PET sheet extrusion production line is a strategic and continuously improved model of the company. This equipment company adopts a special price sales model to ensure market share, with the same parameter configuration achieving low prices, and continuous technological upgrading to ensure that it is always in the first tier of the PET industry. The processed materials can be processed into APET, PETG, RPET, etc.

Introduction to the classification of PET sheet extrusion production lines:

1. PET sheet single screw production line: APET, PETG, CPET sheet single screw extrusion production line is currently a mature and stable production plan, generally using single or double machine co extrusion form. Jinwei adopts new technology, which increases the comprehensive efficiency of this type of machine by 30%

2. PET sheet single screw exhaust production line: This model only requires crystallization of PET and does not require drying. Its advantages include low energy consumption, simple process, convenient equipment maintenance, and the ability to ensure 18CM deep cup vacuum molding.

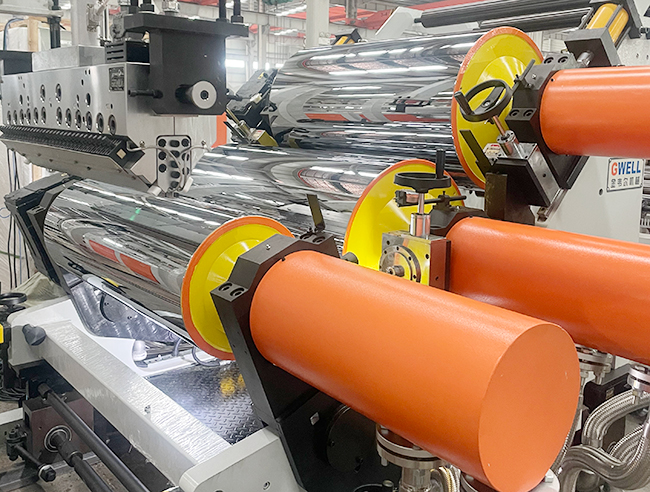

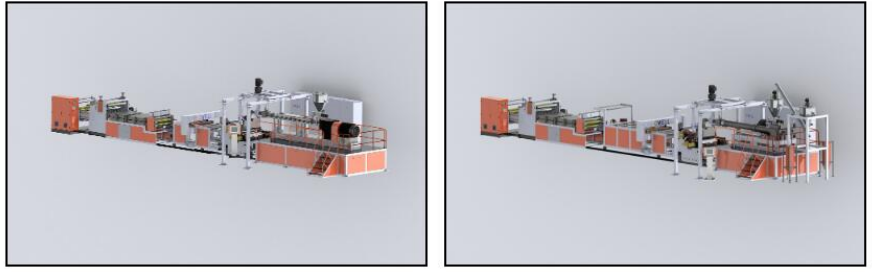

3. PET sheet twin screw exhaust production line (non crystallization drying): The non crystallization and non drying exhaust type PET sheet unit launched by Jinwell has the advantages of low energy consumption and high efficiency. This model is a continuously improved and upgraded product of Jinwell Company, and has made a major technical upgrade to the core vacuum system. It has been upgraded from the original Roots water ring pump group to the Roots rotary vane pump group, which can achieve a vacuum degree of ≤ 10Pa,, At the same time, the use of PET specialized alloy steel thin-walled roller groups significantly improves cooling efficiency, thereby increasing production, improving product toughness, and transparency. The independently programmed operating system of Jinwei ensures the humanization and easy operation of the equipment.

4. PET sheet planetary multi screw exhaust production line (non crystallization drying): Using a planetary screw extruder as the main unit, the increased area of material and air is increased, and in conjunction with Jinweixin

The vacuum system developed can meet the needs of customers with high production and high-quality sheet materials.

(This figure is a schematic diagram of the parallel twin screw exhaust extrusion production line for crystallization free drying PET sheets.) (This figure is a schematic diagram of the planetary twin screw exhaust extrusion production line for crystallization free drying PET sheets.)

Using multiple coextrusion machines to produce multi-layer coextrusion composite PET sheets, such as APET/PETG, PETG/PET/PETG, APET/RPET/APET, and other multi-layer composites. Widely used in blister hot forming, printing, hardware bags, gift folding, etc.

*Equipped with precision distributors, evenly layered, adjustable proportions for each layer, and digital display.

*The inclined horizontal pressing structure makes operation and maintenance more convenient.

*Roller independent transmission, synchronous closed-loop control of linear speed and extruder speed, fully servo system.

*The entire machine adopts Siemens PLC control, achieving automatic control of parameter setting, data calculation, feedback, alarm and other functions.

*The operating program and control system are independently written by Kinwell.

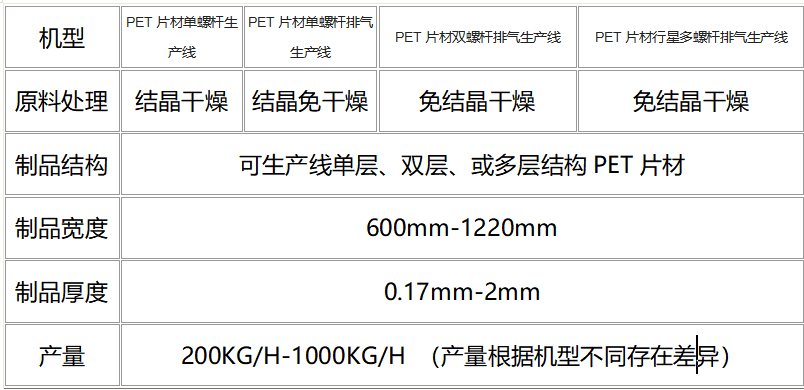

Basic parameters of PET sheet extrusion production line (please consult sales engineer for details)

.

.

G/H-1000KG/H (Production varies depending on the model)

- Previous article:first a piece of writing

- Next article:PET Sheet extrusion production line