product details

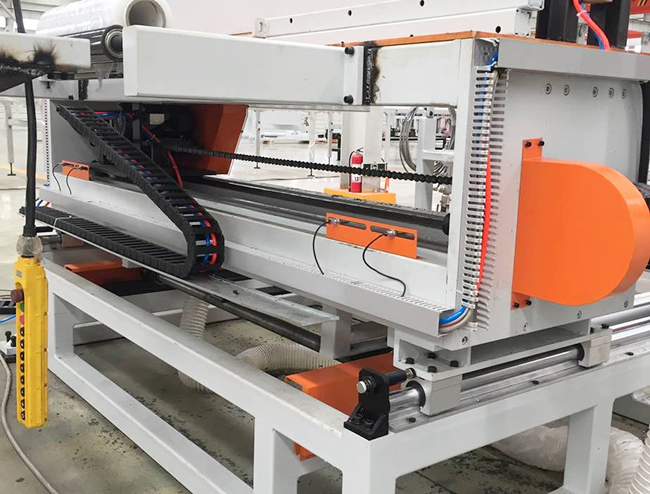

Jinwei Company specializes in manufacturing a new type of PP hollow building template production line. This unit consists of two single screw extruders or single screw and parallel twin screw extruders. After co extrusion, it passes through hydraulic mesh changer, mold, shaping machine, primary traction machine, annealing furnace, cooling box, secondary traction machine, cross cutting machine, and conveyor, providing a complete set of production equipment for multiple enterprises. In the industry, the initial O-shaped hollow structure has been changed to rice shaped, V-shaped, N-shaped, and well shaped structures, and has been changed to a well shaped structure. The well shaped structure is accepted by the market in terms of material usage and structural performance. Its production products have smooth and clean surfaces, small dimensional errors, and many advantages such as nailability, planability, corrosion resistance, and strong flame retardancy. Compared with traditional templates, building templates have the following characteristics:

1. Good water resistance. Even if it is completely immersed in water for many days, it will not deform due to moisture. Acid and alkali resistant, corrosion-resistant, and less prone to decay and rust, especially suitable for use in humid environments such as basement engineering, bridge piers of highways and railways.

2. It is not compatible with cement and adheres, making it easy to demould after construction and will not deform due to cement adhesion.

3. The surface of the plastic template is smooth and smooth, without the need for applying release agents, reducing cleaning and maintenance costs. The surface of the building constructed with it is smooth and flat, without the need for secondary decoration.

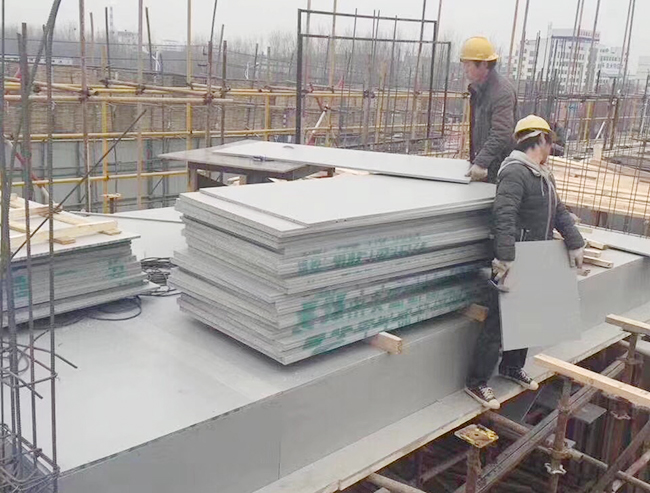

4. Lightweight, efficient in use, easy to support and remove formwork, low labor intensity in handling operations, and high in construction efficiency.

5. High support strength, not easily deformed, resistant to impact and wear.

6. Low cost, long service life, and over 100 cycles of turnover. And the waste boards and leftover materials after use can be recycled, saving costs and reducing pollution. The comprehensive use cost can be saved by more than 30% compared to traditional wooden templates.

7. Long service life and frequent reuse. Damaged plastic templates can still be crushed again and reprocessed into new templates, saving resources and meeting the requirements of "green industry".

8. Good insulation is beneficial for shortening the construction period.

9. Various treatments can be carried out using the method of adding wood, and welding can also be carried out, so secondary processing can be flexibly carried out on the construction site.

10. Plastic templates have good processability, which can be planed, sawn, nailed, and used together with wooden templates;

11. The process is saved and the construction efficiency is improved. The two surfaces (smooth or patterned) of PP hollow plastic building templates have different usage effects. If a smooth surface is used after the concrete pouring is completed and the formwork is removed, the surface of the compacted body is flat and smooth, meeting the requirements for finishing and decorative clean water. There is no need for secondary plastering, which saves materials and time, reduces cleaning and maintenance costs, and the quality is stable after the concrete is formed, saving time. If a patterned surface is used, it is beneficial for bonding with the plaster layer. Especially for bridge piers, the use of patterned surfaces meets the requirements for decorative and clean water. Additionally, due to the special diffuse reflection effect of the patterned surface, it avoids the impact of strong light reflection on the driver's line of sight and provides safety protection.

In short, plastic templates have the commonalities and more advantages over conventional building templates. Plastic formwork will undoubtedly become an ideal product for global construction in the 21st century, replacing wood with plastic, steel with plastic, and bamboo with plastic.

Products are widely used in:

Transportation industry: ships, airplanes, buses, train carriages, ceilings, core layers of carriages, and interior decoration panels. Construction and decoration industry: building exterior wall panels, interior decoration panels, residential, office, public space building partitions, commercial decoration frames, dust-free room panels, ceiling panels, kitchen utensils, and sanitary ware.

Advertising industry: screen printing, computer engraving, advertising signs, display boards, and sign boards.

Industrial applications: chemical industry anti-corrosion engineering, hot formed parts, cold storage boards, special cold insulation engineering, and environmental protection boards.

Other uses: templates, sports equipment, breeding materials, seaside moisture-proof facilities, water resistant materials, various lightweight partitions for art materials.

- Previous article:PP Hollow building template production line

- Next article:PP Hollow building template production line