product details

Light guide plate - application: The light guide plate thin light box is an advertising carrier developed by drawing inspiration from the backlight technology of LCD televisions, and its characteristics are as follows:

1. The appearance is beautiful, and its thickness is generally less than 3 centimeters, which improves space utilization, beautifies the environment, and expands the application range.

2. Bright light plane output, with its optical characteristics not only applied in public places, but also in technology fields such as precision display, photography and medical viewing, scientific research, and standard lighting.

3. Another commendable advantage of it is its energy efficiency, as it uses light emitting technology with a light guide plate, which consumes only 23% of the power of an ordinary light box with the same screen area.

4. The high brightness translucent light tubes used in the thin light box have an average service life of over 8000 hours; The average service life of cold cathode lamp tubes is over 15000 hours. The service life of the light tube used in the thin light box is 5 to 10 times that of a regular light tube. The extension of service life has saved maintenance costs.

5. The thin light box adopts an imported aluminum alloy open type overall frame structure, equipped with movable hooks or hanging holes, making the installation and screen replacement of the light box simple and fast, labor-saving, time-saving, and cost-effective.

Jinweier Machinery GPPS Light Guide Plate Production Line PMMA Light Guide Plate Equipment, Diffusion Plate Production Line:

Application field of diffusion plates: Light diffusion plates are used in liquid crystal displays, LED lighting, and imaging display systems. Their main function is to diffuse incident light, achieving a softer and more uniform illumination effect.

A. Application of diffusion plates in liquid crystal displays

Applied to the direct down backlight system used in LCD TVs, the diffusion plate has good performance such as heat resistance, dimensional stability, mechanical strength, and flame resistance, as well as high light transmittance, shielding, and durability, making it suitable for direct down backlight units

Product characteristics

Light source diffusion: suitable for straight down backlight modules, which can improve the diffusion effect of uniform distribution of backlight sources.

Light transmittance: The light transmittance produces high brightness.

Dimensional stability: Low water absorption, able to maintain good dimensional stability in humid environments

Anti static performance: It has good surface anti static performance and prevents dust adsorption.

B. Application of Light Diffusion Board in Lighting

Requirements for light diffusion plates for LED lighting:

1. Diffusion performance: high light softness;

2. High transparency performance: reduce energy consumption and improve the illumination of lamps;

3. Impact on the light source: Maintain consistency in the color temperature of the light source.

GPPS board

Usage: Widely used in instruments, instrument parts, lighting fixtures, decoration, building materials, aircraft, automotive parts, medical equipment, craft products, electrical insulation materials, specimens, signs, and various light industry, cultural and educational, daily necessities, etc.

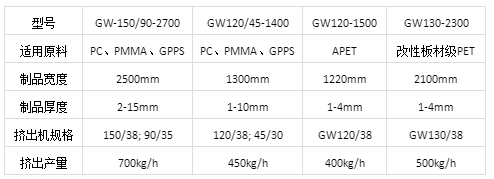

Technical parameters:

Note: The above specifications and parameters are subject to change without prior notice

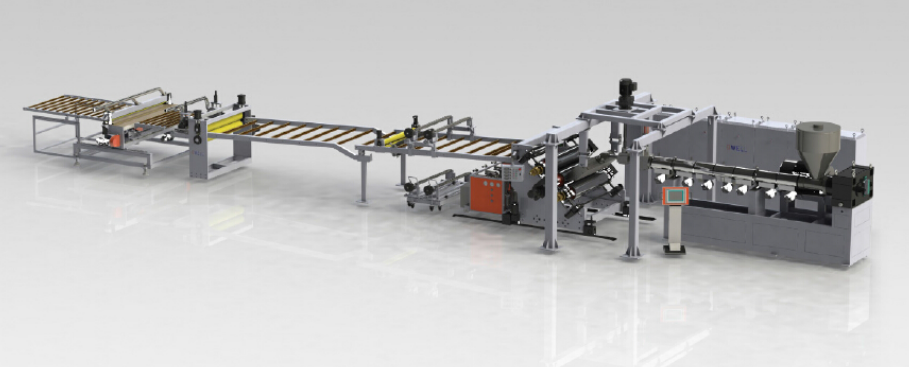

The manufacturer of GPPS light guide plate production line, LED diffusion plate production line, and PS light diffusion plate equipment produced by Jinwei Machinery Co., Ltd. has a high degree of automation in the production line, and only 2-3 people are required to operate one production line. Low energy consumption, currently the production line adopts energy-saving motors, frequency converters, etc., which saves energy consumption and improves efficiency. Jinwei Machinery is committed to building a technology-based enterprise. We have a mature team that integrates management, production line design and development, manufacturing, debugging and operation, after-sales service, and technical training. We provide customers with comprehensive, efficient, and high-quality services such as project feasibility study, scheme demonstration and production, production line manufacturing, equipment debugging, operation training, and after-sales maintenance.

- Previous article:PMMA GPPS Diffusion board production line

- Next article:PMMA GPPS Diffusion board production line